Screw

Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

What Is Screw?

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread.

Advantages of Screw

A Mechanical Edge

When you choose screws, you get a mechanical advantage in the process. Driving in a screw uses less energy when compared to hammering in a nail into the same material. So for those using hand tools, then the project instantaneously easier when screws are used. And the same goes for the use of power tools, which require less force and place less strain on the tool’s motor.

Extra Strength & Long-Lasting Hold

Screws are very strong and are built to last. This is a stark contrast to nails, which may come loose over time. This happens when the materials they connect with begin to expand and shrink over time. Screws are built to resist this problem. Their hold is longer-lasting and stronger. And since screws are so strong, there is less of a worry about the durability and hold. So it gives the material more of a piece of mind when done.

Rust Resistant

Since screws offer a strong and tight bond with their adjoining material, this makes them less susceptible to rusting. The tight hold prevents moisture and contaminant from coming into contact with the screw’s shaft, thus preserving it for a long-lasting hold. So, even if the head of the screw begins to rust, the shaft will remain intact and hold due to this preservation. This advantage makes screws a much better choice than nails for a long-term hold.

Many Different Sizes & Shapes

There are many different sizes and shapes for screws and they come with varying thread patterns. So you can get one specifically designed for use on wood, drywall, sheet metal, concrete, or more. When you use the proper screw type, it improves the long-term use of a screw. Screws also utilize different types of heads, which makes them suitable for use with different types of tools. And thus, easier to complete a job, since you have more tools at your disposal to use.

Easy to Remove

When it comes to removal, there is no fastener that is easier than screws. Of course, you can remove nails and staples. However, you likely need a special tool to get them out. With a screw, they back out of their slots with the same tool that drove them in. So you don’t need to go looking for a different tool and can save that time working.

Reuse Screws

Due to the strength and longevity of screws, you can reuse them more when compared to nails. They seldom bend during the removal, so they can be reused for another application. You can also reinsert them into the same hole without sacrificing strength.

Countersunk Screw

It is a type of screw used in lumber, where it is sunk with its head under the material’s surface, and it is later filled with filler or wood plug. Often, several other types of screws and bolts are also used for a similar purpose. It is quite easy to work with these, and one can even avail of a countersink screw set, where fasteners of different sizes are available.

Pan Head Screws

Similar to the oval head screws, these are majorly used as machine screws and have flat heads with two rounded sides. Being a machine screw, you can avail these in different shapes and sizes. It is generally used in the application of metal elements where the tapered side remains on the underside of the head and can be installed with just a screwdriver.

Self Drilling Screws

Made from hard stainless steel, which prevents rust and corrosion, the self-drilling screws comes with an added feature. These are primarily used in sheet metals and are easy to install in a pre-drilled hole. These are also the thread-cutting screws that can be used to cut the machine threads. However, there are a lot of configurations, which make them ideal for diverse usages like industrial and construction.

Set Screws

Also known as the grub screw, the set screws are generally used to add extra security to the particular object. The object can be either attached from within or with another object. The usage of the nit is, however, optional in this case. Unlike other screws, it is easy to identify because of its headless body. You can notice machinery threads all along its body and that too, in several dimensions. It is essential to keep an internal wrenching drive during the installation of the screw and to fasten it properly.

Threaded Screw

Threading is something that is present in all the screws and can be used on any surfaces and objects widely. It is designed with helical grooves, which help to dig the materials from the object, where the screw is put into. However, there is an absolute difference between the two types of screws, that is, the fully threaded ones, and the partially threaded ones.

Wood screws

As the name implies, it is used to fasten a wooden workpiece. Brass, steel, and bronze are the most frequent materials used to make them. They come in a range of heads and have various threads. Their smooth shank and tapering point are perfect for penetrating the wood.

Weld screws

To hold the object with a nut and washer, these must be welded to a metal surface with a shaft. By using a strong electrical impulse to melt a specially constructed spot on the screw and subsequently on the plate, the screw is first welded to the plate. They come in low carbon, stainless steel, heat-treated, and plated varieties.

Hex cap screws

They are hexagonal locks with six sides that have a perforated hex head on the head and a washer face on the bearing surface. Its six-sided shank or shaft has multiple applications. These kinds of fasteners are employed to join metal or wood. Its hexagonal head evenly distributes force for strong fastening and dependable security. They have chamfers and tight tolerances on their body dimensions.

Thread cutting screws

They have sharp edges because the depth of the hole is somewhat more than the length of the fastener. This tool will prevent the metals from becoming trapped inside the apparatus. They frequently work with metal and wood. As they engrave their way into the substrate, they scrape away pieces of the material in which it is applied.

Carriage bolts

These bolts are employed to secure wood to metal or metal to metal. They are a specific kind of hexagonal bolt used in woodworking, specifically for mounting metal to wood. These have a domed head design that can prevent one-sided loosening. An expanded head form prevents the bolt from being pulled through a wooden structure. Its shank is rounded all the way around, and its shallow mushroom head sets it apart from other bolts.

Material of Screw

Steel

This is the commonest material in which the screws are made out of. They also happen to be some of the cheapest as well. It is important to have a good idea of the type of environment in which the screw will be used, since this will also determine which subtype of steel screw to get. For instance, if the screw is going to be subjected to large forces, you would be better off using the special high strength steel screws.

Aluminum

These tend to be very expensive compared to other types of screws. However, they have a number of distinct advantages which makes them worth it in some cases. For instance, they are very light, which means that they are the ideal types of screws to be used when weight is an issue. In addition to that, they can also be polished to a shine, which is useful in case the screws need to have aesthetic value as well.

Copper

This offers the best resistance against corrosion. Copper screws are therefore of benefit in environments where this is very important, such as in the assembly of items that will be used in saltwater conditions. In order to make it stronger, the copper is normally mixed with a metal such as nickel.

Beryllium

These happen to be extremely light. However, the fact that this metal is brittle means that the screws made out of it are not widely used especially in cases where the shear forces are high.

Titanium

This is a metal that offers the best of both world when it comes to lightness and strength. Screws made out of titanium are mainly used in aircraft, though some other industries such as the automotive industry have also started using it as well. The only drawback to using titanium screws is that they are very expensive.

Connecting the materials: Screws are essential for joining multiple materials safely and effectively, like assembly of metal structures, electronics, and furniture, as they offer a solid and lasting connection.

Connecting wooden elements: Stainless metal screws find extensive application in carpentry, construction, and assembly of furniture. The threads on the screws allow ease of insertion in the material and a stronghold.

Equipment and machinery assembly: Stainless steel screws are essential for assembling multiple machine pieces. These Stainless Steel 304 fasteners offer resistance to vibrations. The rotational torque on these screws makes it a top fastener choice for holding together machine parts.

Structural support: One of the top applications of stainless steel screws is building and bridge construction. These accessories are also useful for fixing columns, beams, and more. Screws offer a reliable and strong connection, ensuring the structure remains safe and sturdy.

Maintenance and repair: Screws are perfect for applications requiring frequent maintenance and repair of the different system parts. Hence, they are used for repairing appliances, screws, and more.

Automotive sector

Fasteners like screws find applications in automobile manufacturing as they help assemble the automobile components like engines, body panels, suspension systems, etc. These accessories ensure safety and reliability.

Electronics

Screws are essential for the security of different elements in electronic devices like smartphones and laptops as they provide reliability and precision.

Construction sector

One of the top applications of screws is the construction industry. Screws are essential for operations like roofing, drywall installation, framing, and fixing fittings and fixtures.

The 5 Key Parts of a Screw

Head

The head of a screw is its topmost part and serves as the primary contact point for tools during installation. There are many different types of screw heads and drive types (which we’ll cover later in the article). You can also categorize screw heads by being countersunk or non-countersunk. Countersunk is when the head rests evenly with the material surface after installation. Non-countersunk is when the head protrudes the material surface after installation, leaving the head exposed.

Shank

The shank refers to the main body of the screw, which connects the head to the tip. It has a pivotal role in determining the screw’s load-bearing capacity and resistance to shear forces. The shank’s length and diameter vary depending on the application, ensuring optimal strength while considering space constraints. Additionally, the shank may feature unthreaded portions, known as the shoulder or body, for specialized applications.

Threads

Threads are the distinctive ridges spiraling around the shank of a screw, responsible for creating a strong and secure connection. They engage with the mating surface, generating friction and preventing the screw from loosening under load. There are various standards used to define thread characteristics. UTS dictates standards only for inch threads, not metric.

Drive

The drive is what determines which type of screwdriver or fastening tool must be used to install and remove a screw.

Internal drives require a tool that inserts into the screw head, like a screwdriver. Phillips, slotted, and socket heads are some internal drive examples. Here’s a photo of a wood screw with one.

External drives require a tool that wraps around the screw head, like a wrench. Hex, hex flange, and square heads are some external drive examples.

Tip

Located at the opposite end of the head, the tip, or point, initiates contact with the material being fastened. Different point designs cater to specific applications. For instance, self-drilling tips enable screws to penetrate metal without the need for pre-drilling, saving time and effort. Self-tapping tips create their own threads in materials like wood or plastic. Sharp tips are ideal for precise placement in delicate applications.

First, you need to choose the right screw for your application. Certain factors come into place when choosing a screw, such as its durability, weight, cost, and type of project you are working on.

Stainless steel screws are inexpensive and work best for all applications. If you need extra durability against corrosion, copper screws are your best bet. For lightweight, aluminum is a good choice. Titanium is both lightweight and durable, but it is costly.

Next, you need to consider the materials you are working with. Wood screws are for joining pieces of wood such as furniture, for example. You need a screw that will withstand the material of your project. If you are working with outdoor materials, you need screws with a coating that can withstand harsh elements.

Grab a screwdriver or drill and put on gloves and safety gear if needed. Make a plot hole and begin screwing until the screw is tight if you are using a screwdriver. Don’t use excessive force or you might damage the material being used. If you are using a drill be careful to use the right speed to avoid overheating or burn marks. A clamp can be used to avoid slips.

Wire Drawing: Transforming Raw Material

The journey of a screw begins with the wire drawing process. A coil of high-quality steel wire is carefully drawn through a series of dies, reducing its diameter while increasing its length. This step ensures that the wire reaches the desired thickness, a critical factor in making screws of various sizes and strengths.

Heading: Shaping the Foundation

With the wire drawn to the appropriate thickness, it is now time for the heading process. The wire is cut into shorter pieces known as blanks. These blanks are then sent to the heading machine, where the foundation of the screw takes shape. Using a punch and die, the machine molds the blank into the desired head shape, laying the groundwork for the final product.

Thread Rolling: Forming Precision Threads

Once the screw blanks have undergone heading, they move on to the thread rolling machine. Here, the magic happens as the machine presses the blank between two dies. The material flows and shapes into the distinctive helical grooves, creating the screw's threads. This precise thread rolling process ensures that the threads are uniform, strong, and perfectly aligned, essential for the screw's functional efficiency.

Heat Treatment: Strengthening the Core

A pivotal step in the screw manufacturing process is heat treatment. The screws are heated to specific temperatures and then rapidly cooled to achieve the desired material properties. This process not only enhances the screws' hardness and strength but also ensures they possess excellent durability, enabling them to withstand the rigorous demands of their applications.

Surface Coating: Protecting and Enhancing

To enhance the screws' resistance to corrosion and improve their appearance, surface coating is applied. Various coating options are available, such as galvanizing, zinc plating, or adding protective coatings like chrome or black oxide. These coatings shield the screws from rust and provide aesthetic appeal, making them suitable for both functional and decorative purposes.

Sorting and Packaging: Ready for Deployment

With the screws now fully formed and coated, they undergo a meticulous sorting process. Sorting machines classify the screws based on their sizes and specifications, ensuring precision and accuracy. Once sorted, the screws are carefully packaged in boxes or bags, ready for distribution and use in various industries worldwide.

Common Mistakes And Solutions When Using Screws

Excessive Force

When this is done during screw tightening, it can result in many problems, such as breaking the screw, ruining the material, or stripping the threads. Attain the required tightness by gradually applying pressure using an appropriate torque setting.

Using the Wrong Type

Weak connections and poor performance can arise from choosing the incorrect type of screw for your application. Always match the screw to the material and project specifications to guarantee a tight fit.

Ignoring Pre-Drilling

If you omit the pre-drilling phase, the wood may split, or the screw may break, especially if the material is dense or hardwood. When required, take the time to pre-drill holes.

Mixing Metals

To stop galvanic corrosion, keep items made of different metals apart, and don’t combine screws with them. To ensure compatibility, stick to materials with similar qualities.

Troubleshooting

While screw problems might be annoying when working on a project, many issues have simple fixes:

Stripped Screws

Use a rubber band or a specialist screw extractor tool if the screw’s head or threads become stripped and challenging to turn. To remove the screw, place the rubber band or extractor over it, press firmly down, and rotate counterclockwise.

Screws Not Holding

It may be necessary to use larger screws or anchors to provide additional stability if screws are not holding firmly in their intended holes. Make sure the spot is the right size and depth, and if needed, think about choosing a more substantial material.

5 Things You Should Look at When Determining the Size of a Screw

There are two systems for determining screw sizes — the metric and the imperial systems. The difference lies in the unit of measurement. For example, while the imperial system measures thread size, length and diameter in inches, the metric system does it in millimeters. Each method has unique characteristics and considerations for determining a screw size.

The diameter of the screw you choose depends on the materials you work with and the hold or anchor required. Using the correct diameter for safe and accurate application is also vital. The screw’s thickness should match the material’s width to avoid tears.

The thread is the spiral shape that runs around the screw’s cylinder. The thread size may differ depending on the diameter of the screw. The threads can be tapered or parallel, or full or partial. Thread per inch (TPI) is the number of threads in one inch of the screw. This typically follows the screw gauge. For example, a screw labeled #10x36 has a #10 gauge and 36 threads per inch.

The screw’s length is essential when choosing the right screw size. While thicker materials may require longer fasteners for a firm hold, short screws may be suitable for thinner materials. The general rule is that the screw should enter at least half of the attached material’s thickness. The screw length is determined by the shaft size, which is the part of the screw inserted into the material. This rule generally applies to non-countersinking screws such as round, hex, button, truss, round and pan-head screws.

Know the material you will work on with the screw, whether wood, metal, PVC, concrete or plaster. Different screw types are suitable for varying materials. Each screw type has a unique build and characteristics to optimize its application.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

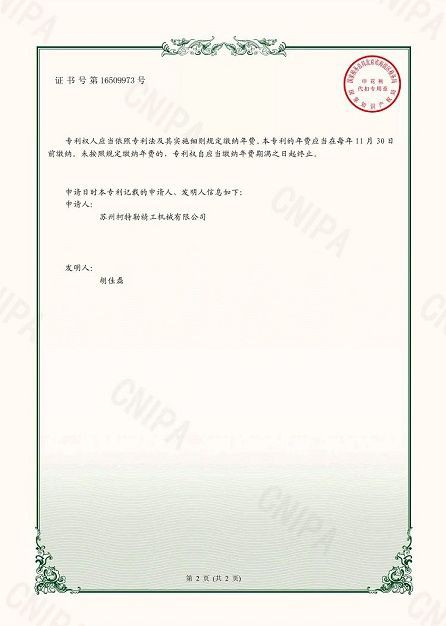

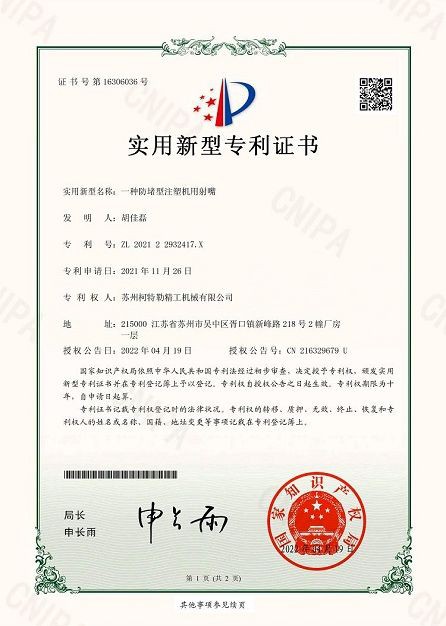

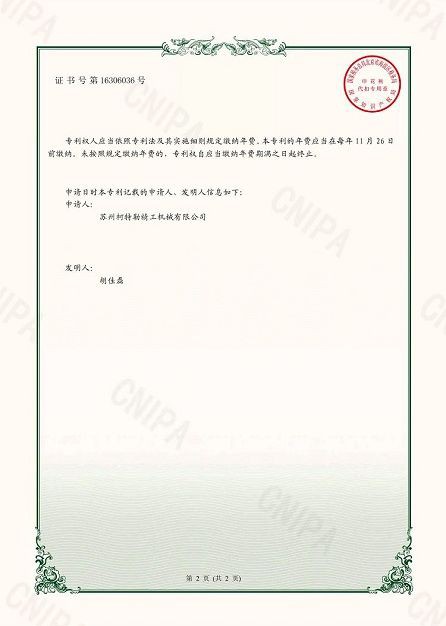

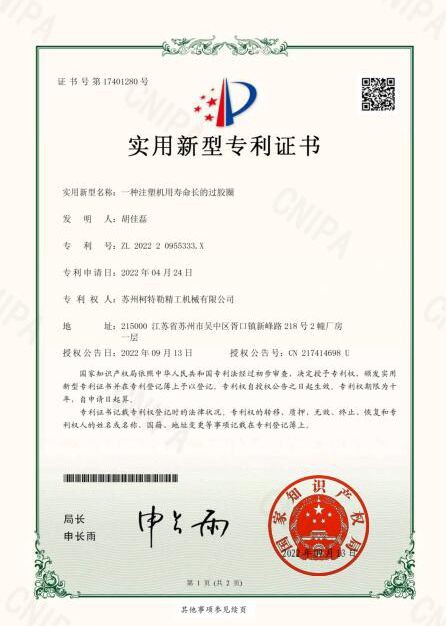

Our Certifications

Ultimate FAQ Guide to Screw

We're well-known as one of the leading screw manufacturers and suppliers in China. Welcome to buy high quality screw in stock here and get quotation from our factory. Contact us for customized service.

Extruder screw for appliance foam extrusion, Extruder screw for flexible foam extrusion, screw recovery time injection molding