Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

The screw is a key component responsible for conveying and plasticizing plastics. Through its rotation, it pushes the plastics forward, achieving compaction, melting, mixing, and homogenization. The screw thread consists of different functional sections to ensure effective conveying, compaction, mixing, and plasticizing effects, as well as high output.

Fully Hardened Alloy Screw For Injection Molding Machine

CNC full grinding thread, good concentricity between outside diameter and root diameter, makes the shear heat of the screw during glue melting will not cause excess friction heat

Bimetallic Screw For Injection Molding Machine

PTA (Plasma Transferred Arc) automatic alloy spaying is a newly applied technology, especially for precise requirement of screws. Comparing to traditional manual alloy spraying, PTA has better performance with the stability and outlook of screws.

Replacing conventional bimetallic screws in the market with non- wear resistance, alloy cracking, not resistant to corrosion, difficult to clean and change colors, unstable melting glue, and poor ejection

Nitrided Steel Screw For Injection Molding Machine

Automatic CNC lathe, milling machine equipment, deep hole boring machine, up to 10m depth nitriding and automatic heat treatment equipment; Professional operators to ensure the accuracy of each process; Various mixing heads design to meet the plasticizing requirements of different plastics.

Extruder Fully Hardened Alloy Screw

We use imported or local made special steel materials for fully Hardened Screws, After series of quenching & annealing process, to achieve high toughness & hardness, they are especially suitable for high wearing materials and production processing. High toughness and hardness.

HVOF (High Velocity Oxygen Fuel) coating process is a kind of thermal spraying technique that melted (or heated) materials are sprayed into the surface. By HVOF technology, alloy powder spraying is under high pressure and high velocity.

Sintered Hard Alloy Screw For Injection Molding Machine

Sintered screw, a very high corrosion resistance and wear resistance.

Extruder Sintered Hard Alloy Screw

Sintered screw, a very high corrosion resistance and wear resistance

Corrosion-resistant and wear-resistant halogen-free special screw for injection molding machine

Simplicity and Cost-Effectiveness: Small extruder screws are relatively simple in design and construction, making them cost-effective to manufacture, operate, and maintain. They are often more affordable compared to their twin-screw counterparts.

Wide Range of Materials: Small extruder screws can process a broad range of materials, including plastics, rubber, metals, and food products. This versatility makes them suitable for various industries, such as plastics manufacturing, food processing, and pharmaceuticals.

Easy to Operate: These extruders are user-friendly and relatively easy to operate, making them suitable for operators with varying levels of expertise. Their straightforward design simplifies the learning curve.

Compact Design: Small extruder screws have a compact design, which is advantageous for facilities with limited space. They can be integrated into production lines more easily due to their smaller footprint.

Energy Efficiency: They are often energy-efficient, consuming less power compared to twin screw extruders, especially when processing certain materials. This can result in cost savings over time.

Low Maintenance: Their simple design reduces the complexity of maintenance and repairs, resulting in reduced downtime and lower maintenance costs.

Consistent Output: Small extruder screws offer consistent and uniform output, making them ideal for applications where product quality and consistency are paramount.

Small Extruder Screw Is the Main Factor Affecting the Quality of Plasticization

Length to Diameter Ratio of Small Extruder Screw: The length to diameter ratio of the small extruder screw refers to the ratio of the effective working length to the diameter of the screw. A larger ratio facilitates better mixing.

1. For plastics with good thermal stability, a longer screw can be used to improve mixing performance without causing overheating.

2. Plastics with poor thermal stability may require a shorter screw or no screw tip to prevent scorching.

3. Typical flow length ratios: thermosetting plastics are 14-16, rigid PVC and high-viscosity PU are 17-18, ordinary plastics are 18-22, and high-temperature stable plastics like PC and POM are 22-24.

Compression Ratio of Small Extruder Screw: Considering material compressibility, fill level, and backflow:

1. A proper compression ratio increases plastic density, tightens molecular separation, reduces air entrainment, and controls temperature rise and output differences.

2. Improper compression ratios can compromise plastic physical properties.

3. Higher compression ratios are suitable for non-melting plastics with low viscosity and thermal stability, while lower ratios suit fusible plastics with high viscosity and heat sensitivity.

Back Pressure of Small Extruder Screw: Increasing back pressure enhances work on molten resin, eliminates unmelted particles, and increases raw material density in the barrel:

1. Back pressure raises barrel temperature, especially affecting heat-sensitive plastics.

2. Excessive back pressure can cause sallies in low-viscosity plastics and bubbles in injection-molded waste.

Rotation Speed of Small Extruder Screw: Rotation speed directly influences plastic shear in the screw's spiral grooves:

1. Shallow screw grooves absorb heat quickly, promoting plastic softening in the compression section.

2. Low friction heat between the screw and barrel wall supports high-speed rotation and enhances plasticization capacity.

3. Large screws should avoid high speeds to prevent uneven plasticization and excessive heat.

4. For heat-sensitive plastics, excessive rotation speeds can lead to undesired synthesis.

5. Typically, screws have recommended speed ranges (100-150 rpm), with speeds too low failing to compact plastic and speeds too high risking scorching.

Electric Heating Temperature of Small Extruder Screw: Melting chilled plastics in the barrel facilitates screw rotation and provides localized heat for plastic melting:

1. Set temperature 5-10°C lower than melt temperature, with additional heat from friction.

2. Nozzle temperature adjustment controls issues like drooling, condensation, and wire drawing.

3. Standard temperature control is used for crystalline plastics.

How To Disassemble The Small Extruder Screw?

1. Remove the nozzle and disconnect it from the extruder barrel.

2. Disconnect the key connection at the rear of the small extruder screw elements from the drive shaft.

3. Remove the connecting flange and slide the extruder screw forward.

4. Once the screw head is exposed, immediately unscrew the connecting thread (note: these threads are generally left-handed).

5. Remove the check ring and sealing ring from the screw.

6. Clean the disassembled nozzle, check ring, sealing ring, and screw immediately using copper brushes and shovel tools while they are still hot. For stubborn residues, heat them in an oven at the lowest temperature that softens the material, then remove the residue.

7. Assemble the parts onto the extruder screw and apply molybdenum disulfide heat-resistant grease to each threaded connection to facilitate future disassembly.

8. After cleaning the unused surface of the screw, apply protective oil, wrap it securely, and store it in a ventilated and safe place.

Causes of Wear in Small Extruder Screws

Abrasion

One of the primary causes of wear in small extruder screws is abrasion. Friction and pressure within the extruder barrel create an environment where abrasive wear thrives. Hard particles such as glass fibers, calcium carbonate, and flame retardants in the polymer gradually erode the surfaces of the screw and barrel. This abrasive effect intensifies at high pressures and temperatures. Surface hardening techniques like nitriding and chrome plating can enhance screw element durability against abrasion.

Corrosion

Corrosive wear results from chemical attacks by additives and degraded polymer particles, which can chemically corrode extruder components. Exposure to corrosive materials or high temperatures can lead to corrosion and pitting on extrusion screw elements. Corrosive wear is particularly common in the metering zone, where elevated temperatures and prolonged material residence times increase the risk of product degradation. Surface treatments are effective in mitigating the effects of corrosive wear.

Overheating in Small Extruder Screws

Excessive heat generated during extrusion can induce thermal degradation, directly causing wear on screw elements. Uneven heating of the cylinder exacerbates this issue, underscoring the importance of maintaining consistent temperature profiles. Implementing effective insulation and cooling systems helps regulate temperatures, reducing the risk of thermal wear and enhancing the extrusion system's overall performance and longevity.

Fatigue in Small Extruder Screws

Repeated stress and pressure cycles over time can lead to fatigue wear, gradually weakening small extruder screws. This cumulative damage can compromise the screw's structural integrity, potentially resulting in failure. To mitigate fatigue wear, ensuring proper alignment of the screw within the cylinder is essential. Regular maintenance and inspections are crucial for detecting early signs of fatigue, enabling timely interventions to prevent catastrophic failures.

Small Extruder Screw Length-Diameter Ratio

The ratio of the length of the working part of the screw to the diameter of the screw is called the length-diameter ratio. When other conditions are constant (such as the diameter of the screw), increasing the length-diameter ratio means increasing the length of the screw. A larger aspect ratio and a reasonable temperature distribution are conducive to mixing and plasticization of plastics. The extended heating time in the barrel ensures more thorough and uniform plasticization, thereby enhancing plasticization quality.

Given that plasticization quality requirements remain unchanged, increasing the length-diameter ratio allows for higher screw rotation speeds, thereby increasing the plastic extrusion volume. However, choosing an excessively large aspect ratio will correspondingly increase the power consumption of the screw. Moreover, it will increase the complexity of processing and assembling the screw and barrel, potentially leading to screw bending. This can cause scraping between the screw and barrel walls, reducing their service life.

Furthermore, for heat-sensitive plastics, excessively high aspect ratios can result in thermal degradation due to prolonged residence time, affecting plasticization and extrusion quality. Therefore, the selection of the aspect ratio should be based on the physical properties of the processed plastics and the quality requirements of the extruded product.

The gap between the screw and the barrel is half of the difference between the inner diameter of the barrel and the outer diameter of the screw. The size of this gap significantly impacts the quality and output of extrusion, especially regarding plasticization.

When the gap between the screw and the barrel is too large, particularly when it increases in the homogenization section, it exacerbates counterflow and plastic leakage. This not only causes fluctuations in extrusion pressure and affects the extrusion volume, but also leads to overheating of the plastic due to increased backflows. This overheating, especially in environments with poor heat dissipation, often results in plastic decomposition, leading to poor plasticization and challenging molding processes. Therefore, the gap between the screw and the barrel is generally maintained within 0.1 to 0.6 mm.

A large lead thread should be used at the charging port to ensure smooth material discharge.

In the melting section, a small lead thread should be used to build up pressure. Additionally, a 30° angled pinch block can be utilized for the initial distribution of mixing. Note that the pinch blocks should be spaced out.

In the mixing section, the primary goal is to shear, refine, and disperse the material particles. This section requires complex setup of thread elements, necessitating designers with extensive practical experience. Staggered angles of 45° and 60° for pinch blocks are primarily used here to enhance shear, assisted by special elements such as tooth-shaped elements or "S" shaped elements.

Reverse threaded elements or reverse pinch blocks should be positioned before the exhaust port or vacuum port. Large lead threaded elements should be placed at the exhaust port or vacuum port, while small lead threaded elements should be positioned after.

In the homogenization section, the thread lead should be tapered to increase pressure and reduce the length of the back pressure section. Simultaneously, attention should be paid to using single-ended threads and wide-pronged threads to enhance discharge capacity and prevent material bubbling.

Maintenance of Small Extruder Screws

Check thoroughly if the screw is twisted, and assess the extent of damage to the barrel. If the barrel can still be used, consider its actual inner diameter when determining the outer diameter deviation for manufacturing the new screw.

After treating the worn screw with a reduced diameter on its thread surface, apply a hot-sprayed wear-resistant alloy, thickening it by 2-3 mm, and then grind it to size. This type of production requires the expertise of technical professionals from screw barrel manufacturers skilled in spraying processing maintenance.

Apply overlay welding with a wear-resistant alloy to the threaded part of the worn screw. Depending on the degree of wear, overlay welding should be 1-2 mm thick, followed by grinding the screw to size. This type of wear-resistant alloy typically includes materials like C, Cr, Vi, Co, W, and B, enhancing the screw's wear and corrosion resistance. This processing is costly and usually performed by specialized overlay welding facilities, except for specific screw requirements, which are generally rare.

Alternatively, the maintenance screw can be surface-plated with hard chrome. Chromium is also wear-resistant and corrosion-resistant, although the hard chrome layer may be prone to peeling off.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

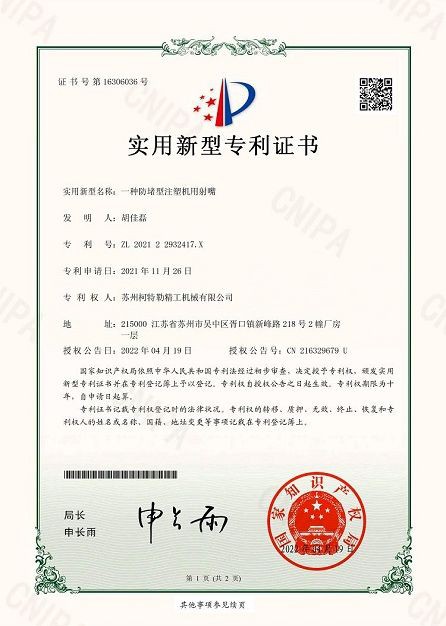

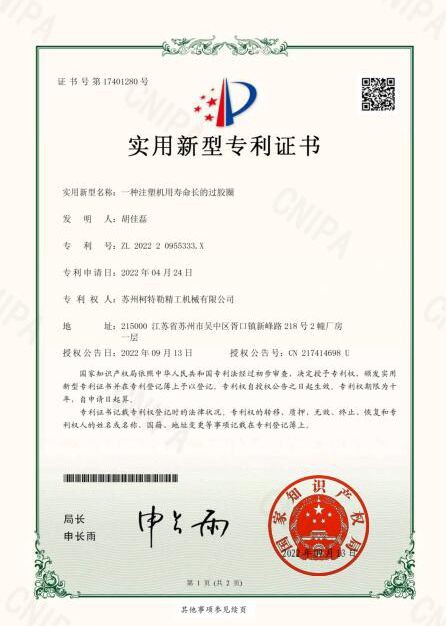

Our Certifications

Ultimate FAQ Guide to Small Extruder Screw

Hot Tags: small extruder screw, China small extruder screw manufacturers, suppliers, factory, Extruder screw for foam wire extrusion, Extruder screw for low density foam extrusion, Extruder screw for antistatic foam extrusion, Extruder screw for foam sheet extrusion, twin screw injection molding, screw rotation speed injection molding