Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

An extruder bimetallic screw is a specialized type of extrusion screw designed with a two-layer construction, hence the term "bimetallic." The hard inner core provides the necessary strength and rigidity to withstand the high stresses and abrasion encountered during the extrusion process. The bimetallic screw design enhances the overall performance, efficiency, and lifespan of the extruder, making it a valuable component in modern extrusion processing equipment.

Fully Hardened Alloy Screw For Injection Molding Machine

CNC full grinding thread, good concentricity between outside diameter and root diameter, makes the shear heat of the screw during glue melting will not cause excess friction heat

Bimetallic Screw For Injection Molding Machine

PTA (Plasma Transferred Arc) automatic alloy spaying is a newly applied technology, especially for precise requirement of screws. Comparing to traditional manual alloy spraying, PTA has better performance with the stability and outlook of screws.

Replacing conventional bimetallic screws in the market with non- wear resistance, alloy cracking, not resistant to corrosion, difficult to clean and change colors, unstable melting glue, and poor ejection

Nitrided Steel Screw For Injection Molding Machine

Automatic CNC lathe, milling machine equipment, deep hole boring machine, up to 10m depth nitriding and automatic heat treatment equipment; Professional operators to ensure the accuracy of each process; Various mixing heads design to meet the plasticizing requirements of different plastics.

Extruder Fully Hardened Alloy Screw

We use imported or local made special steel materials for fully Hardened Screws, After series of quenching & annealing process, to achieve high toughness & hardness, they are especially suitable for high wearing materials and production processing. High toughness and hardness.

HVOF (High Velocity Oxygen Fuel) coating process is a kind of thermal spraying technique that melted (or heated) materials are sprayed into the surface. By HVOF technology, alloy powder spraying is under high pressure and high velocity.

Sintered Hard Alloy Screw For Injection Molding Machine

Sintered screw, a very high corrosion resistance and wear resistance.

Extruder Sintered Hard Alloy Screw

Sintered screw, a very high corrosion resistance and wear resistance

Corrosion-resistant and wear-resistant halogen-free special screw for injection molding machine

Improved Wear Resistance The hard, wear-resistant inner core of the bimetallic screw provides superior resistance to abrasion, erosion, and corrosion compared to a standard screw. This results in a significantly longer service life before the need for screw replacement.

Enhanced Thermal Efficiency The combination of the two metal layers improves the thermal conductivity of the screw, allowing for more efficient heat transfer and melting of the extruded material. This contributes to improved product quality and consistency.

Tailored Material Compatibility The outer corrosion-resistant layer can be matched to the specific chemical and thermal requirements of the extruded material, improving compatibility and reducing the risk of material degradation.

Reduced Screw Wear and Damage The hard inner core of the bimetallic screw is less susceptible to wear and damage from abrasive fillers or reinforcements in the extruded material. This helps maintain dimensional stability and consistent performance over the screw's lifetime.

Improved Melt Quality The enhanced thermal efficiency and wear resistance of the bimetallic screw contribute to better melt homogeneity and reduced defects in the extruded product.

Increased Production Uptime The longer service life of the bimetallic screw means less frequent screw replacements, leading to fewer production interruptions and more reliable operation.

Versatility in Applications Bimetallic screws can be designed and customized for a wide range of extrusion applications, including thermoplastics, elastomers, and even food and pharmaceutical products.

Tool Steels: These are popular due to their hardness and durability. Specific types include:

D2 Steel: Known for its high wear resistance and ability to hold a sharp edge.

M2 Steel: Offers good wear resistance and toughness.

Nitrided Steels: These are treated with a nitrogen-hardening process to increase surface hardness.

4140 Steel: A chromium-molybdenum alloy steel, often used because of its balance of strength and toughness.

4340 Steel: Another chromium-molybdenum alloy, with added nickel for greater toughness.

Stainless Steels

Used for their corrosion resistance.

17-4 PH Stainless Steel

Precipitation-hardened stainless steel that offers a good combination of strength and corrosion resistance.

316 Stainless Steel

Known for its high corrosion resistance, especially in harsh environments.

How to Deal with Black Spots in the Extruder Bimetallic Screw

Most extruder processing materials, such as PE, PVC, and TPU, do not have long thermal histories, so black spots can occur if they remain in the bimetallic screw for too long. Large extruders with barrels connected to the die, featuring longer flow channels and storage tanks, are more prone to black spots due to hidden residues in corners and dead ends. Black spots often appear when the machine stops. How can you clean the black spots from the screw after stopping?

The bimetallic screw can completely remove impurities, but the time required is minimal, and impurities in the barrel and die may not be effectively treated. Frequent adjustments to the screw can also challenge machine precision. To minimize these issues, it's advisable to avoid unnecessary screw changes.

Special cleaning materials for extruder black spots are available and can effectively clean black spots from the machine. After resolving black spots, it's important to identify their source to focus on prevention. This approach is more time and cost-efficient while ensuring normal production. For example, black spots often occur when the machine is shut down. Using shut-down maintenance materials can prevent residual materials from decomposing and carbonizing, thus avoiding black spots.

What Performance Requirements Must the Screw of a Twin Screw Extruder Meet?

Mechanical Strength

The screw is a crucial component of the twin screw extruder, directly affecting the plasticizing effect and material output. It must continuously push materials at high speeds and withstand significant friction and corrosion from plastic decomposition. A screw with high mechanical strength ensures continuous material movement.

Torque

During high-speed plasticizing and forming operations, the screw must shear and plasticize the plastic while relying on substantial torque to drive the material through the barrel. The screw must handle high temperatures and pressures in the barrel.

Resistance to Deformation

The screw must endure high temperatures and pressures during material formation and extrusion. It should resist deformation to ensure effective plasticization of materials.

The extruder bimetallic screw operates under high pressure, high temperature, high mechanical torque, and high friction, leading to inevitable wear. Surface nitriding treatment improves wear resistance, but addressing the causes of wear is crucial to extend screw life.

Controlling the barrel temperature to match the ideal plasticizing temperature range is important. In the feeding section, dry friction occurs, and insufficiently heated or unevenly melted plastics increase wear on the barrel and screw. Proper speed adjustment is also necessary, especially when using reinforcing agents like glass fibers or minerals that cause more wear. High rotational speeds increase shear forces and produce more shredded fibers, exacerbating wear.

Overall quenching treatment can address issues with chrome layer wear and environmental protection. This treatment is suitable for various special engineering plastics, such as glass fiber, PPA, PO, PPS, LCP, ABS, bakelite powder, magnetic powder, and PC.

Melting and Mixing A well-designed screw efficiently conveys material from the hopper to the barrel, providing adequate shearing and mixing for uniform melting. Poor melting and mixing lead to inconsistencies in the product.

Temperature Control Screw geometry affects temperature control within the barrel. An optimized design maintains the desired temperature profile, preventing overheating or underheating.

Pressure and Flow Control The screw design influences pressure buildup within the extruder, which is crucial for preventing melt fracture or instability. Proper design maintains consistent material flow.

Residence Time Excessive residence time can lead to material degradation or over-melting, negatively impacting product quality.

Output Rate and Throughput Proper screw design helps achieve desired production rates without overloading or underutilizing the extruder.

Die Pressure and Profile Control Screw design affects die pressure, influencing the shape and dimensions of the extruded product. Optimized design maintains consistent die pressure and controls the product's cross-sectional profile.

Material Compatibility Screw design should match the characteristics of the processed material. Different materials may require specific screw geometries to achieve the desired quality.

Material Degradation Screw design can affect the thermal and shear degradation of the plastic material. Excessive degradation reduces mechanical properties and overall quality.

How to Prevent the Extruder Bimetallic Screw from Slipping

Screw slippage can cause material to gather at the feeding port, preventing proper conveyance. Slippage occurs when the screw rotates but does not move axially, often due to excessive back pressure, overheating or undercooling, wear, shallow thread design, or hopper issues.

Overcooling at the end of the conical screw barrel is a major cause of slippage. The barrel is divided into three sections, and in the feeding section, a melt film forms and sticks to the screw. Inadequate heating can prevent this film from forming, leading to slippage. Small injection machines often face this issue due to insufficient residence time, resulting in incomplete melting and mixing, causing slippage or stalls.

Why Should the Extruder Bimetallic Screw Be Cooled?

The extruder bimetallic screw, made of high-quality alloy steel (such as 38CrMOALA or SACM645), offers high wear and corrosion resistance. Cooling the screw during extrusion is crucial to prevent material decomposition from high plasticizing temperatures.

Cooling in the feeding section prevents excessive heat buildup, avoiding material attachment and ensuring smooth conveyance. The homogenization section also requires cooling due to heat generated by extrusion, friction, and shearing. Cooling is achieved using water or oil passed through the screw via axial holes, controlled at a constant temperature. Special pipe fittings, called rotary joints, connect the screw to the heat transfer medium pipeline.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

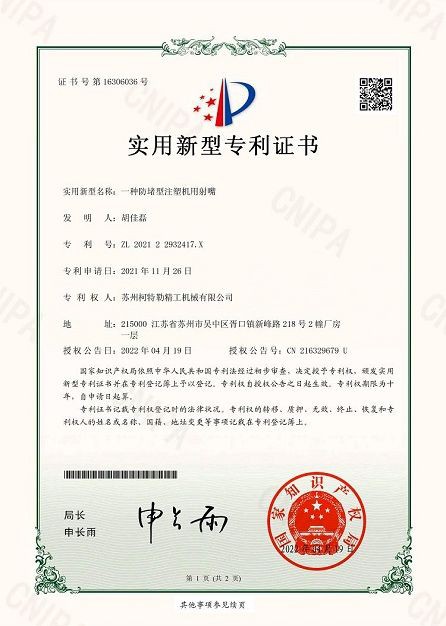

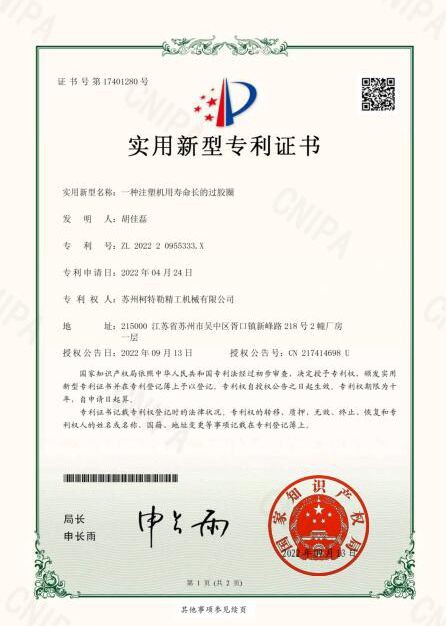

Our Certifications

Ultimate FAQ Guide to Extruder Bimetallic Screw

Hot Tags: extruder bimetallic screw, China extruder bimetallic screw manufacturers, suppliers, factory, Extruder screw for foam rubber extrusion, Extruder screw for conductive foam extrusion, Extruder screw for foam pelletizing extrusion, Extruder screw for HDPE foam extrusion, Extruder screw for textile foam extrusion, Extruder screw for HDPE foam processing machines