Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

The extrusion barrel is a critical component in the extrusion process. It is a cylindrical chamber that houses the extruder screw. Barrels are typically made of hardened, wear-resistant steel alloys to withstand the high temperatures, pressures, and abrasive nature of the extrusion process. The extrusion barrel, in combination with the extruder screw, is a crucial component that determines the overall performance, efficiency, and product quality of the extrusion process.

Bimetallic Barrel For Injection Molding Machine

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

A cylinder that surrounds the screw and helps maintain the plastic's temperature and flowability. The barrel also transfers heat to and away from the material, and can have four or more temperature zones, including feed, rear, middle, and front. The barrel is a pressure-carrying vessel that can be made from bimetallic or tool-steel-lined materials.

Screw Barrel Injection Molding Machine

The screw barrel is a cylindrical component of an injection molding machine that's essential for processing plastic materials. It's located between the plasticizing screw and the mold cavity, and it works in conjunction with the screw to make up the machine's extrusion system.

Sintered Hard Alloy Barrel For Injection Molding Machine

Sintered screw, a very high corrosion resistance and wear resistance

Extruder Sintered Hard Alloy Barrel

Sintered barrel, a very high corrosion resistance and wear resistance

Single Screw Extruder Screw Barrel

The screw barrel of a single screw extruder is a hollow cylindrical enclosure that contains a single screw that pushes material through a die to create a product

Extruder Nitrided Steel Barrel

Automatic CNC lathe, milling machine equipment, deep hole boring machine, up to 10m depth nitriding and automatic heat treatment equipment; Professional operators to ensure the accuracy of each process; Various mixing heads design to meet the plasticizing requirements of different plastics.

The extruder screw barrel is a hollow cylinder that surrounds a screw and is a key component in plastic processing machines and food processing. The barrel's purpose is to maintain the temperature and flowability of the material while the screw melts, mixes, and blends raw materials into the desired product.

The extrusion screw barrel is a hollow cylinder that surrounds a screw and is a key component in plastic processing machines and food processing. The barrel's purpose is to maintain the temperature and flowability of the material while the screw melts, mixes, and blends raw materials into the desired product.

Efficient Material Feeding and Melting: The barrel design and its interactions with the rotating screw enable effective feeding, melting, and homogenization of the raw material. This ensures a consistent and continuous supply of molten material to the extrusion die.

Temperature Control and Regulation: Precisely controlling the temperature profile along the barrel length is crucial for achieving optimal melt viscosity and quality. Proper temperature management helps prevent thermal degradation of the material and ensures consistent product properties.

Pressure Generation and Regulation: The barrel, in conjunction with the extruder screw, generates the necessary pressure to push the molten material through the extrusion die. Maintaining appropriate pressure is essential for consistent and defect-free extrusion.

Venting and Degassing Capability: Some extrusion barrels are designed with venting ports or degassing zones to remove volatile components, trapped air, or other impurities from the melt. This helps improve the quality and consistency of the extruded product.

Versatility and Adaptability: Extrusion barrels can be designed and configured to accommodate a wide range of materials, including thermoplastics, elastomers, composites, and even food and pharmaceutical products. Barrel features such as length, diameter, heating/cooling zones, and materials of construction can be tailored to specific application requirements.

Improved Productivity and Efficiency: The optimized design and temperature control of the extrusion barrel contribute to increased production rates, reduced scrap, and more consistent product quality. This leads to higher overall equipment effectiveness and better profitability for the extrusion operation.

Material of Extrusion Barrel

Nitrided Steel Nitrided steels, such as 41CrAlMo7, are often used for constructing extrusion barrels. These steels undergo heat treatment and surface nitriding to enhance wear resistance, hardness, and corrosion resistance.

Bimetallic Lining In some cases, the barrel may feature a bimetallic lining. This involves applying a layer of wear-resistant material, such as an alloy containing tungsten carbide or Stellite, to the inner surface of the barrel. The outer layer is typically made of a more cost-effective material, such as carbon steel.

Tool Steel Tool steels, such as H13 or D2, are utilized for applications involving high temperatures and demanding processing conditions. They offer excellent toughness, wear resistance, and thermal conductivity.

High-Speed Steel (HSS) High-speed steels, like M2 or M42, are renowned for their exceptional hardness, heat resistance, and wear resistance. They are suitable for processing abrasive materials or applications requiring high temperatures.

Powder Metallurgy Powder metallurgy techniques can be employed to manufacture extrusion barrels. Various materials, including stainless steel, tool steel, or high-speed steel, can undergo powder metallurgy to achieve desired properties such as improved wear resistance and corrosion resistance.

Tungsten Carbide Tungsten carbide, known for its extreme hardness and wear resistance, is often used as a coating or in inserts for critical wear areas of the extrusion barrel to enhance durability.

Integral Type

The integral structure barrel is widely used in extruders, especially in smaller specifications. This type of barrel facilitates the arrangement of heating and cooling devices, ensuring precise temperature control and high machining accuracy.

Sectional Type

The sectional structure barrel is primarily used in larger and vented extruders. It consists of several sections, each of smaller length, which simplifies machining but may pose challenges in achieving consistent inner diameter and concentricity across sections due to flange connections.

Bimetallic Layer Type

This type involves lining or casting the barrel's inner diameter with wear-resistant alloy. Larger extruders typically start with a cast steel barrel, adding a wear-resistant alloy bushing or a cast layer post-finishing to conserve valuable alloy steel.

How Does The Design Of An Extrusion Barrel Affect The Extrusion Process

Melting and Mixing The design of the extrusion barrel determines how effectively raw materials are melted and mixed. Adjusting screw and barrel geometry creates shear forces and mixing zones, facilitating uniform melting and mixing.

Pressure and Flow Barrel design influences the pressure and flow of molten plastic through the extruder. Screw parameters like pitch, flight depth, and number impact material pressure and flow dynamics.

Residence Time Barrel design dictates material residence time inside the extruder. Optimal residence time balances melting and mixing; too short results in inadequate melting, while too long risks material overheating and degradation.

Wear and Tear Barrel design affects durability and wear resistance. Optimized materials and surface finishes minimize wear, maintaining consistent extrusion quality.

Output and Quality Ultimately, barrel design impacts extruder output and product quality. Optimization enhances production rates and product consistency.

Factors Affecting the Performance of Extrusion Screws and Extrusion Barrels

Material Selection

Material choice (e.g., alloy steel, stainless steel, high-speed steel) significantly impacts screw and barrel performance, influencing hardness, wear resistance, and corrosion resistance.

Design Structure

Screw and barrel design parameters such as pitch, thread shape, and heating/cooling methods affect conveying capacity, plasticizing efficiency, and melt quality.

Accuracy Requirements

Machining precision of screws and barrels impacts performance; lower precision leads to uneven melting and mixing, affecting product quality and production efficiency.

Operating Environment

Environmental factors like temperature and corrosiveness influence material selection for screws and barrels, affecting operational performance and longevity.

Extrusion Barrel Alignment Is Essential To The Plastics Extrusion Process

Proper alignment of production machinery is crucial for maintaining optimal equipment performance and producing high-quality products. In plastics extrusion, alignment ensures the rotational centers of components like the screw and gearbox are properly aligned. Misalignment can lead to premature wear, reduced throughput, and other operational issues.

How to Improve Extrusion Barrel Thermal Control for Faster Processing Time

Efficient temperature control in extrusion barrels is critical for optimizing energy usage and process efficiency. Traditional systems often exhibit temperature gradients along the barrel length, impacting uniformity and efficiency. Techniques like Serpentine Flow principles, which create continuous coolant flow through narrow channels along the barrel, improve temperature uniformity and responsiveness. This reduces energy consumption and enhances process stability and product quality.

Repair Welding Plan After Extrusion Barrel Wear

To extend the service life of worn extrusion barrels, surfacing welding with high-chromium tungsten carbide electrodes is effective. This process enhances wear resistance and thermal stability, maintaining barrel integrity and improving longevity.

How To Set Up Optimal Extrusion Barrel Temperatures

Optimizing extrusion barrel temperatures is crucial for product quality and production efficiency. Temperature profiles should be meticulously adjusted based on process requirements and material characteristics to avoid defects and maximize output. Continuous monitoring and adjustment during operation ensure consistent quality and efficient production.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

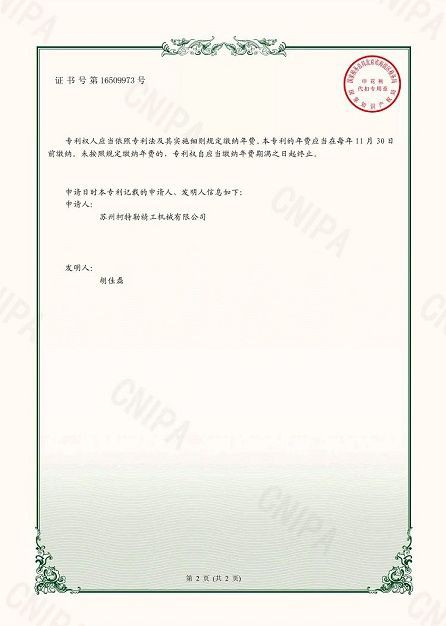

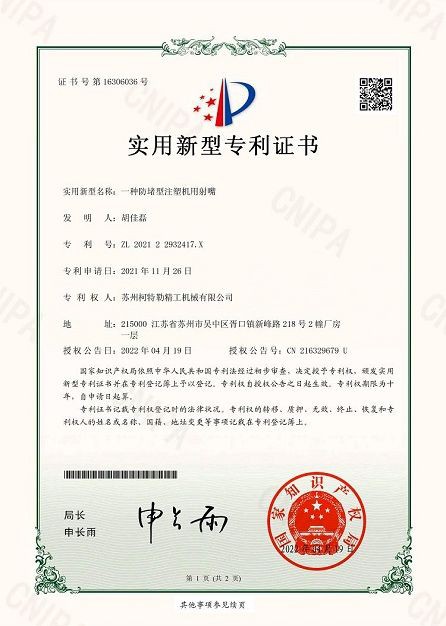

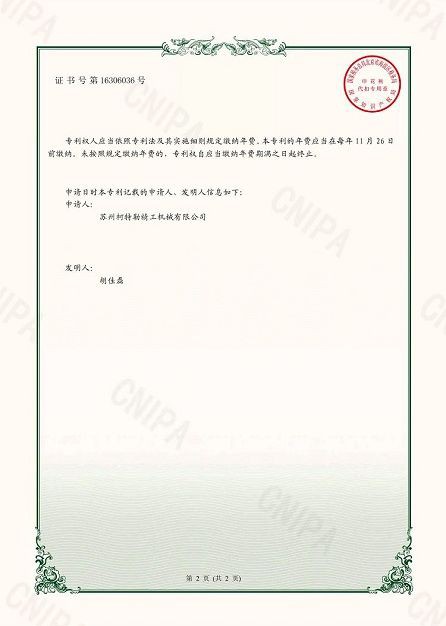

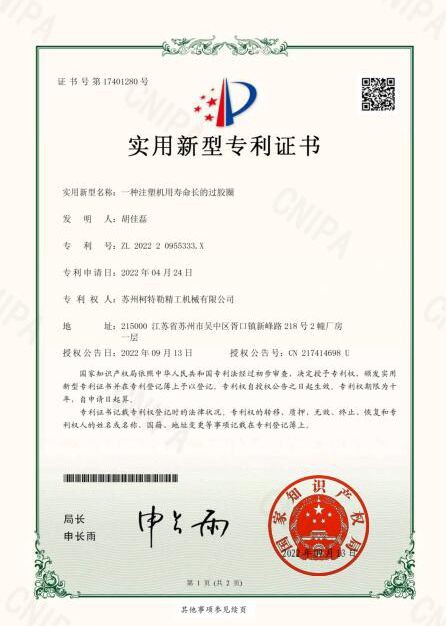

Our Certifications

Ultimate FAQ Guide to Extrusion Barrel

Hot Tags: extrusion barrel, China extrusion barrel manufacturers, suppliers, factory, Extruder screw for medical-grade compound extrusion lines, Extruder screw for PMMA foam extrusion, haitian injection molding screws services for plastics, Extruder screw for PET foam extrusion, Extruder screw for LDPE foam extrusion, injection molding screw zones