Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

An extruder bimetallic barrel is a type of barrel composed of two different alloys or metals. It is designed to enhance the performance and durability of extrusion and injection molding machines. The outer layer typically consists of a wear-resistant material, such as nitrided steel or tungsten carbide, while the inner layer is made of high-strength steel. The design of the extruder bimetallic barrel offers several benefits, including increased resistance to wear, corrosion, and high temperatures. Moreover, the bimetallic barrel design proves to be more cost-effective than a single-material barrel because only the wear-resistant outer layer needs replacement when it wears out.

Bimetallic Barrel For Injection Molding Machine

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

A cylinder that surrounds the screw and helps maintain the plastic's temperature and flowability. The barrel also transfers heat to and away from the material, and can have four or more temperature zones, including feed, rear, middle, and front. The barrel is a pressure-carrying vessel that can be made from bimetallic or tool-steel-lined materials.

Screw Barrel Injection Molding Machine

The screw barrel is a cylindrical component of an injection molding machine that's essential for processing plastic materials. It's located between the plasticizing screw and the mold cavity, and it works in conjunction with the screw to make up the machine's extrusion system.

Sintered Hard Alloy Barrel For Injection Molding Machine

Sintered screw, a very high corrosion resistance and wear resistance

Extruder Sintered Hard Alloy Barrel

Sintered barrel, a very high corrosion resistance and wear resistance

Single Screw Extruder Screw Barrel

The screw barrel of a single screw extruder is a hollow cylindrical enclosure that contains a single screw that pushes material through a die to create a product

Extruder Nitrided Steel Barrel

Automatic CNC lathe, milling machine equipment, deep hole boring machine, up to 10m depth nitriding and automatic heat treatment equipment; Professional operators to ensure the accuracy of each process; Various mixing heads design to meet the plasticizing requirements of different plastics.

The extruder screw barrel is a hollow cylinder that surrounds a screw and is a key component in plastic processing machines and food processing. The barrel's purpose is to maintain the temperature and flowability of the material while the screw melts, mixes, and blends raw materials into the desired product.

The extrusion screw barrel is a hollow cylinder that surrounds a screw and is a key component in plastic processing machines and food processing. The barrel's purpose is to maintain the temperature and flowability of the material while the screw melts, mixes, and blends raw materials into the desired product.

Advantages of Extruder Bimetallic Barrels

Wear Resistance: The primary benefit of extruder bimetallic barrels is their wear resistance. The outer layer is typically made of wear-resistant materials such as nitrided steel or tungsten carbide, which significantly reduces wear and tear during processing.

Corrosion Resistance: Extruder bimetallic barrels are also resistant to corrosion. This is crucial due to the highly corrosive nature of some plastic resins used in processing, which can damage standard barrels. The inner layer, usually made of high-strength steel, provides corrosion resistance.

High-Temperature Resistance: Extruder bimetallic barrels can withstand high temperatures encountered during plastic processing. The outer layer is designed with materials that can endure these temperatures, enhancing barrel longevity.

Cost-Effectiveness: Compared to single-material barrels, extruder bimetallic barrels are more cost-effective. Only the wear-resistant outer layer needs replacement when worn, reducing maintenance costs and downtime.

Plastic Extrusion: Widely used in producing plastic pipes, sheets, wires, and profiles, especially with abrasive materials like PVC, PP, and PE. The wear-resistant inner layer prolongs screw barrel life and ensures uniform material extrusion.

Injection Molding: Ideal for high-wear and corrosion-resistant plastics such as glass fiber reinforced polyamide (PA6-GF), ensuring durability and quality in injection molding.

Plastic Recycling: Essential in recycling processes to handle diverse plastics, enhancing sustainability and product quality.

Cleaning of Extruder Bimetallic Barrels

Barrel Cleaning Methods: Use specialized barrel cleaners for efficient cleaning, especially when changing materials with different processing temperatures.

Refueling and Ejection Method: Adjust heating to match new material plasticization temperatures, ensuring thorough cleaning.

Maintenance During Shutdown: Clean thoroughly and apply anti-rust measures to prevent damage during prolonged shutdowns.

Design Principles of Extruder Bimetallic Barrels

Material Characteristics

Tailor design to specific plastic material properties such as melting temperatures and viscosity for optimal performance.

Process Requirements

Adapt barrel design for different processes like extrusion or injection molding to enhance efficiency.

Product Specifications

Adjust design for different product shapes and sizes, ensuring compatibility and performance.

Use and Maintenance of Extruder Bimetallic Barrels

Routine Maintenance

Regular upkeep ensures operational efficiency and longevity, focusing on cleanliness, lubrication, and part inspection.

Scheduled Maintenanc

Detailed inspection and replacement of worn parts after specified operational hours to maintain performance.

Precautions

Prevent damage from foreign objects, maintain cleanliness, and use appropriate lubricants to ensure smooth operation.

Enhancing Screw Barrel Performance with Bimetallic Composites

Improved Wear and Corrosion Resistance

Utilize hard alloys for wear resistance and corrosion-resistant materials for longevity.

01

Optimized Thermal Conductivity

Enhance heat transfer for efficient processing and reduced energy consumption.

02

Reduced Friction

Minimize heat generation and wear with low-friction materials.

03

Strength and Temperature Resistance

Ensure durability under high pressures and temperatures encountered in processing.

04

Extended Service Life

Longer operational times and reduced downtime with improved durability.

05

Temperature and Processing Considerations

Temperature Control: Maintain precise temperatures for optimal plasticization without overheating.

Heat Distribution: Ensure uniform heat distribution along the barrel for consistent melt quality.

Material Compatibility: Match temperature settings to plastic material requirements to avoid degradation.

Cooling Systems: Use cooling systems as needed to prevent overheating and maintain barrel integrity.

Operational Settings: Adjust screw speed and pressure for efficient processing and reduced wear.

Cleaning and Maintenance: Follow manufacturer guidelines for cleaning and upkeep to maximize barrel lifespan.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

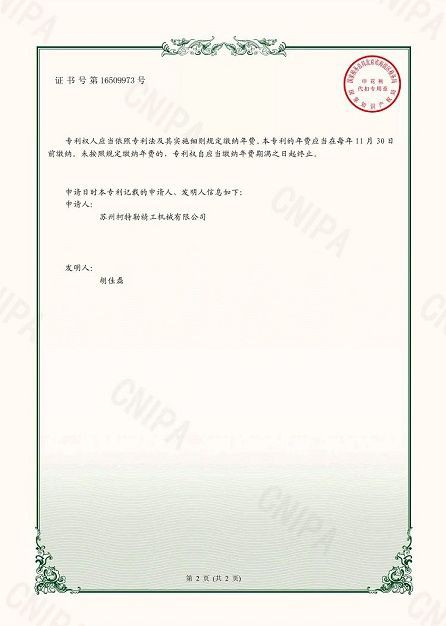

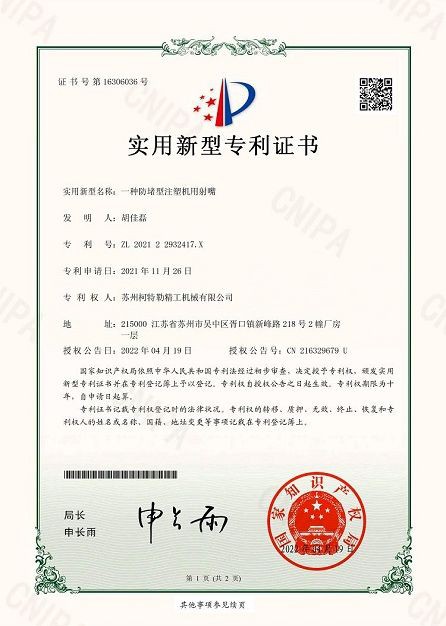

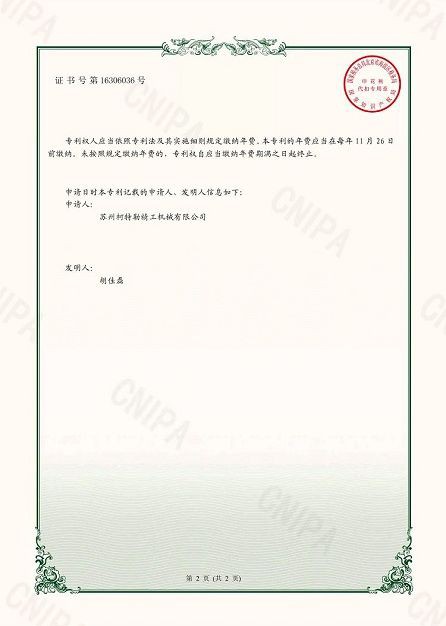

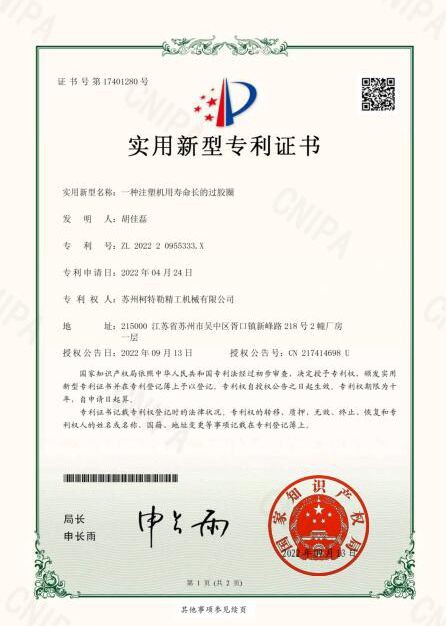

Our Certifications

Ultimate FAQ Guide to Extruder Bimetallic Barrel

Hot Tags: extruder bimetallic barrel, China extruder bimetallic barrel manufacturers, suppliers, factory, plastic injection molding screws, Extruder screw for microcellular foam extrusion, feed screw manufacturers, general purpose screw injection molding, Extruder screw for PET foam processing machines, extruder screws and barrels